In modern manufacturing, precision, and efficiency are two critical factors determining the success of projects involving fabrication and assembly. To achieve this, parametric software has gained undeniable prominence, enabling the generation of programs for Computer Numerical Control (CNC) machines and the creation of precise blueprints.

This type of software optimizes production processes while ensuring quality and consistency in the fabrication of parts and components.

Parametric Software

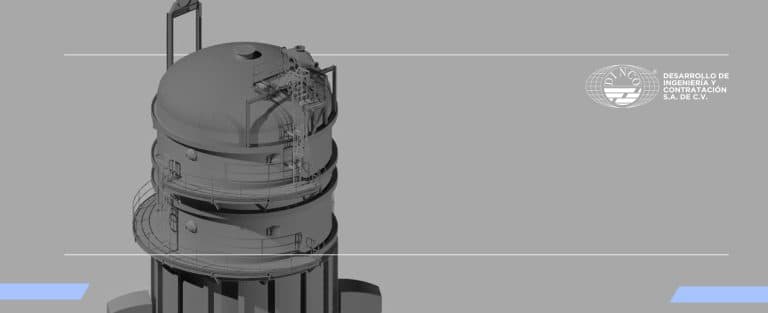

Parametric software refers to Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) tools that allow the creation of 3D models and blueprints based on defined parameters. These parameters can include dimensions, tolerances, materials, and other key factors that define the characteristics of the final product.

Unlike traditional design methods, where each change requires a manual modification of drawings, parametric software allows for automatic adjustments to all design aspects when a parameter is changed. This saves time and reduces the likelihood of errors.

Benefits of CNC Program Generation

CNC machines have revolutionized manufacturing by enabling the production of parts with precision and repeatability that would be impossible to achieve manually. To fully leverage these machines, programs that translate designs into instructions that CNCs can execute are needed.

Parametric software facilitates the creation of these programs by automatically generating the necessary code to operate the machines.

Precise Blueprints for Manufacturing and Assembly

Precision in blueprints is essential to ensure that each component is manufactured correctly and that assembly proceeds without issues. Parametric software ensures that the generated blueprints are consistent with the 3D model, accurately reflecting the design’s dimensions and specifications. This is especially important in industries where tolerances are minimal, such as aerospace or automotive, where any deviation can result in critical failures.

Additionally, the ability to automatically update blueprints when design parameters are modified allows for greater flexibility in product development. If a last-minute change is required, the software adjusts all related elements—from the 3D model to the blueprints and the CNC program—ensuring that the entire manufacturing and assembly process aligns with the new requirements.