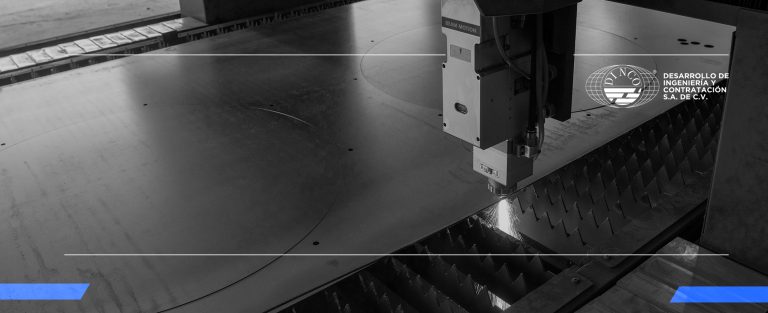

Nesting of beams and plates is an essential technique in industrial manufacturing that maximizes material usage, reduces costs, and improves operational efficiency.

With the help of advanced technology, this process becomes a powerful tool for achieving sustainable and profitable production in industries such as construction, gas, and oil.

Nesting is an optimization process used in manufacturing and material cutting, particularly in the metallurgical industry.

What is Nesting?

Nesting involves the optimal organization and arrangement of pieces to be cut from a material plate or beam, such as steel, to minimize waste and maximize the use of available material. This process is crucial in the fabrication of structural components where multiple pieces of different shapes and sizes need to be cut from large sheets or beams of metal.

Importance of Nesting

- Waste Reduction: Efficient arrangement of pieces reduces material waste, leading to significant cost savings and greater sustainability in resource use.

- Productivity Improvement: Effective nesting allows for faster and more efficient production as pieces are logically and accessibly organized for cutting, reducing operation time and enhancing overall productivity.

- Cost Savings: Minimizing material waste not only saves direct raw material costs but also reduces the time and effort required to handle and process residual material.

- Space and Resource Optimization: Maximizing material usage optimizes storage space and inventory management, enabling a more orderly and efficient workflow.

Tools and Technology in Nesting

The nesting process is often performed using specialized software that automatically calculates and organizes the optimal arrangement of pieces to be cut. These programs consider material dimensions, piece shapes, and specific manufacturing process constraints, offering precise and efficient solutions.

At DINCO, one of the functions of our technical team is the nesting of beams and plates to achieve intelligent resource optimization in each of our clients’ projects.